Why WrkPlan is the Smart Choice for Cutting-Edge

Inventory Management

WrkPlan provides an AI-driven, scalable inventory management system tailored for businesses demanding accuracy and flexibility. Key features include:

-

Multiple Warehouse Management

Efficiently manage inventory across multiple warehouses with WrkPlan’s centralized database and real-time syncing capabilities. This feature allows for precise inter-warehouse stock transfers, geolocation tracking, and comprehensive reporting.

- Centralized Database Architecture

- Inter-Warehouse Stock Transfers

- Warehouse-Specific Inventory Tracking

- Multi-Warehouse Reporting

- Inventory Replenishment Alerts

-

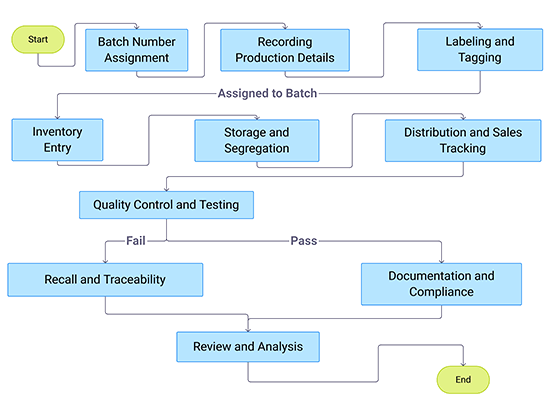

Batch & Serial Number Tracking

Enhance your inventory control with WrkPlan’s Batch & Serial Number Tracking feature, offering precise stock level management, improved quality control, and seamless traceability.

- Effortless Batch Number Tracking

- Serial Number Assignment

- Real-Time Inventory Updates

- Expiry Date Tracking

- Defect Tracking

- Batch-Wise Stock Reports

-

Barcode Integration

Streamline your inventory processes with WrkPlan’s advanced barcode integration. This technology facilitates accurate item identification, stock counting, and efficient management across all warehouse locations, ensuring seamless operations.

- Real-Time Inventory Updates

- Error Reduction

- Batch and Serial Number Tracking

- Integration with Order Management

- Multiple Warehouse Support

- Inventory Forecasting

-

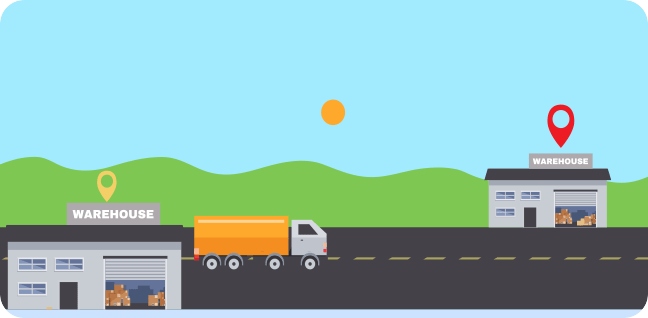

Inter-Warehouse Stock Transfer

Optimize your inventory control with WrkPlan’s Inter-Warehouse Stock Transfer feature, designed to ensure smooth and efficient inventory transfers across multiple warehouse locations. Powered by real-time inventory tracking, advanced automation, and real-time data syncing, this feature ensures accurate stock management and streamlined operations.

- Seamless Stock Movement

- Real-Time Updates

- Detailed Movement Records

- Item Location Tracking

- Multiple Warehouse Coordination

- Automated Adjustments

-

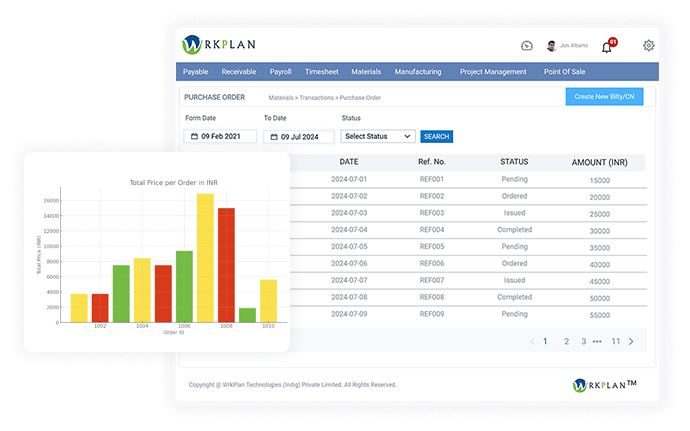

Intelligent Order Management

Efficiently Manage Orders from Start to Finish

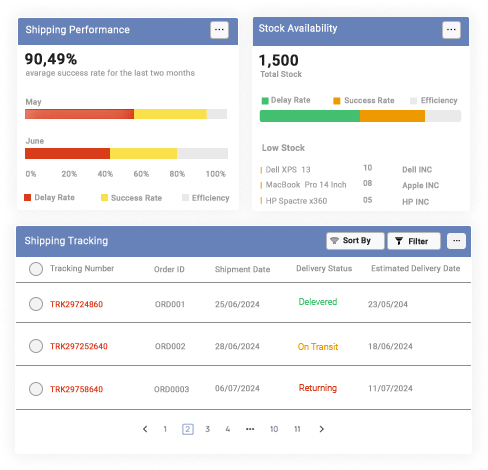

Efficiently manage orders from start to finish with WrkPlan’s Intelligent Order Management system. This solution ensures real-time order tracking and automated order entry, enhancing accuracy, scalability, and customer satisfaction. With smart order fulfillment and real-time data sync, your business can handle complex operations with ease, improving overall efficiency.

- Order Creation and Processing

- Real-time Order Monitoring

- Smart Order Fulfillment

- Shipping Integration

- Omni-Channel Order Management

- Automated Inventory Allocation

-

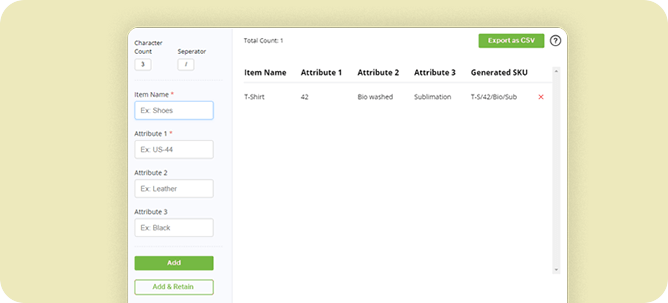

Automated SKU Generation

Improve inventory accuracy and consistency with WrkPlan’s Automated SKU Generation. Customizable patterns and consistent SKU application help maintain detailed inventory records, streamline real-time inventory tracking, and reduce errors across multiple warehouse locations.

- Customizable SKU Patterns

- Consistent SKU Application

- Group-Based SKU Generation

- Pattern-Based SKU Generation

- Unified Inventory System

- Error Elimination

-

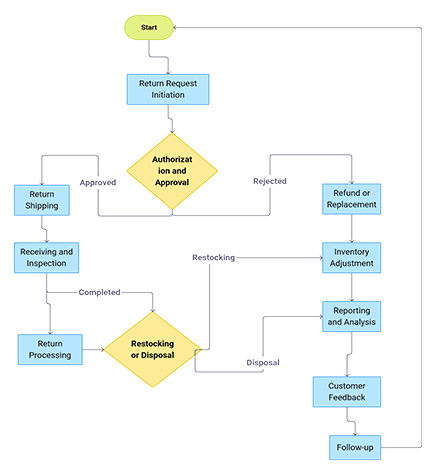

Returns Management with AI Insights

Manage returns efficiently with WrkPlan’s AI-driven returns management system. From automated return processing to real-time inventory tracking and quality control inspections, this feature ensures that your inventory remains accurate and compliant with return policies.

- Automated Return Process

- Quality Control Inspection

- Refund and Exchange Processing

- Return Authorization Management

- Compliance and Policy Management

- Customer Communication and Support

-

IoT-Enabled Real-Time Inventory Tracking

WrkPlan’s cloud-based system ensures that inventory data is continuously updated across all locations. With real-time data sync, instant stock updates, and advanced API integration, discrepancies are minimized, and decision-making is enhanced.

- Instant Updates Across All Modules

- Enhanced Demand Forecasting

- Seamless Integration

- Geolocation-Based Tracking

- Automatic Discrepancy Alerts

- Multi-Device Access

Additional Features

Automated Stock Replenishment

Automatically generate purchase requests when stock levels fall below predefined thresholds....AI-Powered Inventory Classification

Classify inventory into categories like fast-moving, slow-moving, and dead stock for smarter...Real-Time Location Tracking

Track inventory across multiple locations with GPS-enabled geotagging....Kitting and Bundling Management

Assemble inventory into kits or bundles for faster order fulfillment....Cycle Count Automation

Streamline inventory audits with automated cycle counting features....Multi-Channel Inventory Integration

Sync inventory data across sales channels, including e-commerce platforms, distributors, and retail...Inventory Aging Reports

Identify aging stock to prevent obsolescence and manage liquidation effectively....Serialized Stock Alerts

Receive instant notifications about critical stock movements, such as serialized product dispatches...Industries We Serve

Explore our integrated accounting software tailored for various sectors, including:

-

Manufacturing

-

IT Hardware

-

Foods and Beverages

-

Leather Goods

-

Rubber Goods

-

Electronics

-

Textiles

-

Retail

-

Wholesalers

-

E-Commerce

-

Paper Goods

-

Real Estate

Testimonials

Nitesh Patel

Account Manager

The WrkPlan team knows how to keep their promises. We asked them for a few customizations and they did it within just a few days. Now my teams can easily manage taxes without any issues.

Divya Teja

Project Manager

The product quality is consistently outstanding, exceeding my expectations every time I ask for development,I am completely impressed with the service and Response. The Best App .

Neha

Deputy Manager HR

Thank you to the team WrkPlan for your patience and professionalism. We have worked with them to set up a cloud-based ERP on our premises and they executed it within a stipulated time frame. WrkPlan Team is always quick to reply and provide good support!

Experience Seamless Inventory Management

With WrkPlan ERP Inventory and Manufacturing Software - Free Trial!

Sign Up Today and streamline your stock management.

Sign Up Now !Frequently Asked Questions

How WrkPlan inventory management software for small businesses can help in inventory and order management?

WrkPlan is a SaaS-based online inventory management software that provides easy-to-use tools for efficient warehouse management. It efficiently manages and eliminates potential inventory risks such as theft, damage, and expiration. Its high accuracy and speed provide real-time information on stock shelf life and enable small businesses to scale effectively.

Why cloud-based inventory management software is better than old spreadsheets?

Cloud-based inventory software surpasses traditional spreadsheets in terms of speed, accuracy, and data security. Online inventory solutions centralize all inventory data on a single platform,eliminating the need to search for scattered data. They offer real-time insights and automate manual tasks to reduce human errors and enhance overall productivity and efficiency.

How can WrkPlan help my logistics business?

WrkPlan logistics management software offers you a versatile set of tools to streamline your logistics operations. With WrkPlan, you can seamlessly monitor multiple warehouses from one platform, giving you detailed insights into stock levels, and optimizing your supply chain management for better demand forecasting and order fulfilment.

How does stock management software improve accuracy in inventory tracking?

WrkPlan inventory tracking system utilizes advanced technologies like barcode scanning and automated data entry to minimize manual errors. This ensures high accuracy in managing stock levels and can give clear insights to prevent stockouts or overstock situations.

How does the warehouse management system help prevent stockouts and overstock situations?

WrkPlan's warehouse inventory monitoring software offers real-time updates and notifications for low inventory or overstock situations. This helps prevent stockouts and overstock scenarios, enabling timely reorders and maintaining optimal inventory levels to meet demand.

What are some common inventory management threats?

Common inventory management challenges include inaccurate demand forecasting, shelf life expiration, inventory theft, stock damages, and more. WrkPlan's user-friendly inventory management software efficiently addresses these issues, providing cost-effective solutions.

How secure my inventory data are with WrkPlan?

WrkPlan is a cloud-based inventory management software hosted by AWS Cloud Security, enhancing your data security protocols and providing better control over your inventory data. AWS centralizes your inventory data, making it easily accessible while ensuring data security.

How can WrkPlan warehouse and inventory tracking software streamline supply chain management?

With WrkPlan easy inventory management software you can easily streamline your supply chain. WrkPlan offers you real-time visibility, and control over your entire supply chain, optimizes inventory level, and minimizes manual errors to boost your supply chain and handle demands.

Does the WrkPlan inventory system have an SKU generation tool?

WrkPlan provides an easy-to-use SKU generation tool for generating SKU numbers for any specific item or item range.

How can I enable the batch tracking feature in WrkPlan?

Using batch reports, you can utilize the batch tracking feature in WrkPlan.

How can I add the serial number to an item in WrkPlan inventory software?

Whenever a new shipment arrives, you can add the serial number for that shipment.

Can I add or delete items in bulks?

Yes, you can. WrkPlan enables users to add or delete items in bulk easily.

Can I track my inventory by batch number, location or expiry dates?

WrkPlan allows you to track your inventory by batch number, warehouse locations, or item expiry dates in the inventory reports.

Can I customize my inventory reports in WrkPlan?

Yes, you can customize your inventory reports based on your specific business requirements.

Can I manage my inventory for multiple warehouses?

With the WrkPlan inventory management system for warehouses, you can efficiently monitor multiple warehouses and access detailed reports for each warehouse in the warehouse overview report.

Can I move inventory stocks from one warehouse to another warehouse?

Yes, offers an inter-warehouse stock transfer facility, allowing you to move stocks from one warehouse to another within the system.

Are drop shipment facilities available in WrkPlan?

Yes, WrkPlan enables the drop shipment facility, allowing direct delivery of goods to your customers. You can change your shipment method to enable this feature.

What industries does WrkPlan serve?

WrkPlan is a comprehensive inventory solution suitable for businesses of all sizes and industries.

How WrkPlan can assist in reducing inventory costs?

With WrkPlan's inventory management system, businesses can reduce inventory expenses by inventory in real-time, accurately forecasting demand, and optimizing inventory levels. This minimizes costs associated with overstocking or stockouts, such as storage fees, product wastage, and lost sales. WrkPlan enables data-driven decisions on restocking, purchase quantities, and inventory storage to further minimize costs.