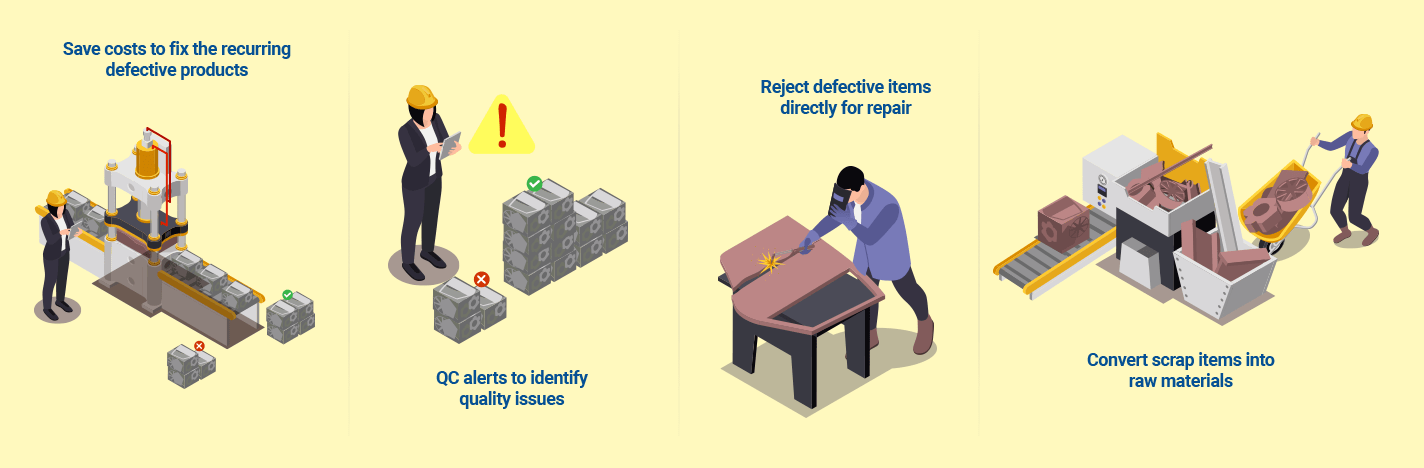

Proactive Defect Identification for Cost Efficiency

WrkPlan’s ERP empowers you to detect and address quality issues early in the production cycle, minimizing costs and ensuring timely interventions. Our integrated quality control features help identify defects before they escalate, enabling you to optimize resources effectively. Whether repairing rejected items or recycling them into raw materials, WrkPlan enhances both efficiency and cost management in your manufacturing process.

- Early Defect Detection: Identify and resolve issues at the earliest stages of production.

- Cost-Effective Quality Management: Minimize the financial impact of defects with timely interventions.

- Resource Optimization: Efficiently manage rejected items through repair or recycling, maximizing resource utilization.