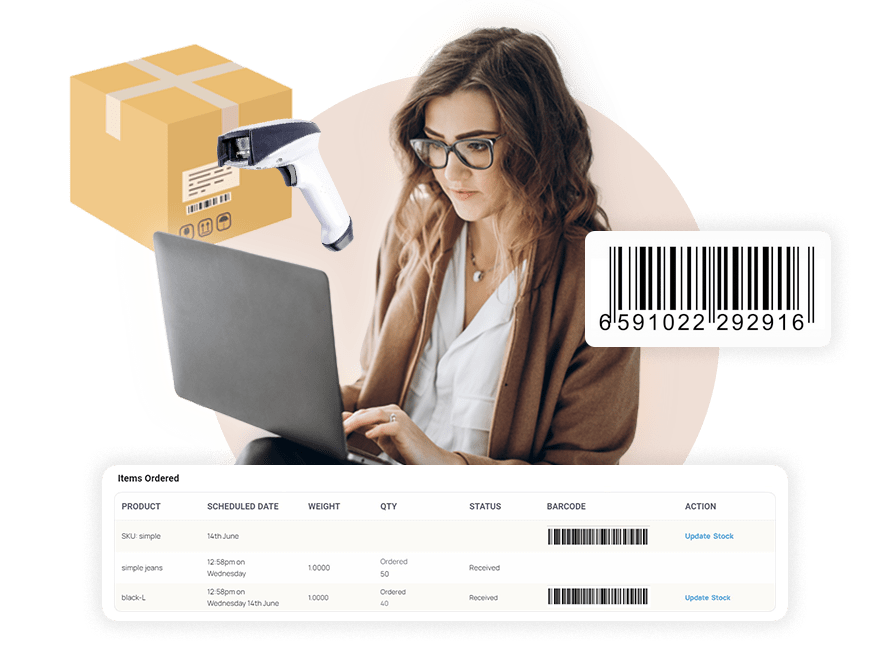

Barcode Integration

Streamline your inventory processes with WrkPlan’s advanced barcode integration. This technology facilitates accurate item identification, stock counting, and efficient management across all warehouse locations, ensuring seamless operations.

- Real-Time Inventory Updates

- Error Reduction

- Batch and Serial Number Tracking

- Integration with Order Management

- Multiple Warehouse Support

- Inventory Forecasting

Key Features and Benefits

Real-Time Inventory Updates

Instant Data Synchronization: Every barcode scan instantly updates inventory levels in WrkPlan’s centralized cloud database, ensuring that all data is current and accessible across all modules. This real-time inventory tracking facilitates immediate decision-making and reduces discrepancies.

Real-Time Data Sync: Keep your inventory data synchronized in real-time across all systems, ensuring accuracy and consistency in stock levels and availability.

Error Reduction

Automated Data Entry: By automating the data entry process through barcode scanning, WrkPlan significantly minimizes the risk of human errors. This leads to more accurate inventory records, smoother operations, and reduced labor costs.

Accurate Item Identification: Ensure each item is accurately tracked with barcode scanning, reducing miscounts and improving inventory reliability.

Batch and Serial Number Tracking

Enhanced Traceability: WrkPlan’s system supports the scanning and tracking of batch and serial numbers, allowing for detailed monitoring of inventory items throughout their lifecycle. This feature is essential for maintaining high standards of quality control and ensuring traceability across the supply chain.

Comprehensive Tracking: Monitor each item’s journey from receipt to sale or production with detailed batch and serial number tracking, enhancing your ability to manage inventory and respond to issues.

Integration with Order Management

Seamless Workflow Integration: Barcode scanning is fully integrated with WrkPlan’s order management module. As orders are processed, inventory levels are automatically adjusted, ensuring accurate stock availability and reducing the risk of overselling or stockouts.

Automated Stock Adjustments: As inventory is received, moved, or sold, barcode scans automatically update stock levels in real-time, ensuring accurate inventory management.

Multiple Warehouse Support

Multi-Location Tracking: The system is designed to manage inventory across multiple warehouse locations. Barcode scanning updates inventory records specific to each warehouse, providing a clear and accurate picture of stock levels and movements across all locations.

Centralized Inventory Management: Coordinate inventory across various locations with real-time updates and centralized control, improving efficiency and reducing stock discrepancies.

Inventory Forecasting

Data-Driven Predictions: Data captured through barcode scanning feeds into WrkPlan’s advanced inventory forecasting algorithms. This integration enables more accurate predictions of future inventory needs, optimizing stock levels and reducing carrying costs.

Proactive Stock Management: Utilize real-time data to forecast inventory needs accurately, preventing stockouts and reducing excess inventory.

Supplier and Vendor Management

Streamlined Supply Chain: WrkPlan’s barcode integration seamlessly tracks inventory as it moves from supplier to warehouse to customer. This ensures that all stages of the supply chain are monitored and managed efficiently, improving vendor performance and delivery accuracy.

Improved Vendor Relations: Maintain accurate records of supplier deliveries and inventory movement, enhancing collaboration and performance evaluation with vendors.