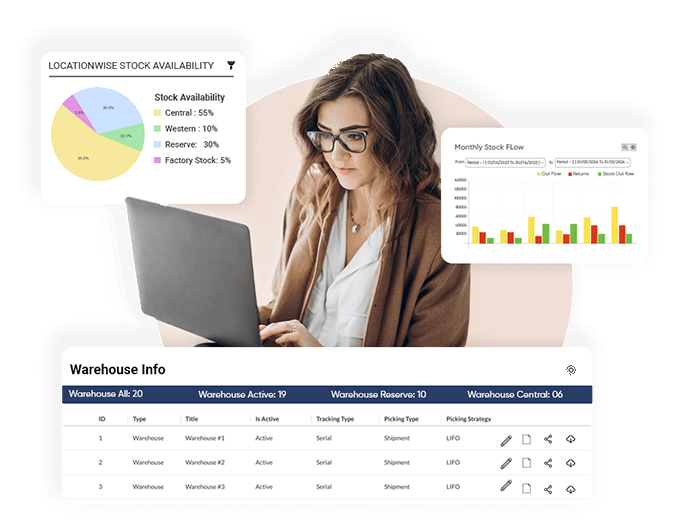

Multiple Warehouse Management

Efficiently manage inventory across multiple warehouses with WrkPlan’s centralized database and real-time syncing capabilities. This feature allows for precise inter-warehouse stock transfers, geolocation tracking, and comprehensive reporting.

- Centralized Database Architecture

- Inter-Warehouse Stock Transfers

- Warehouse-Specific Inventory Tracking

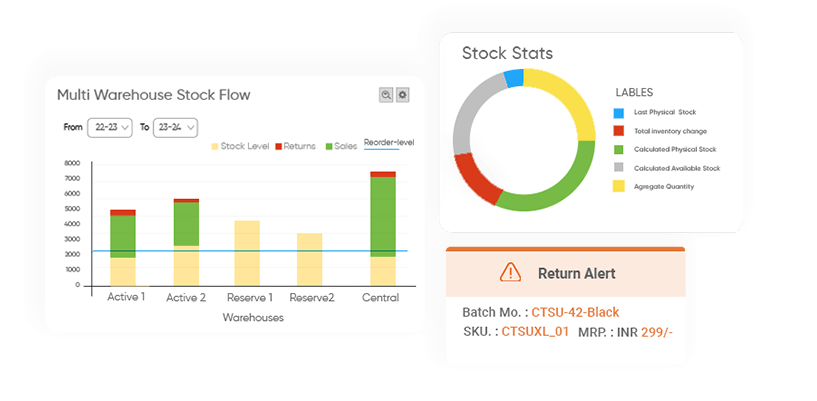

- Multi-Warehouse Reporting

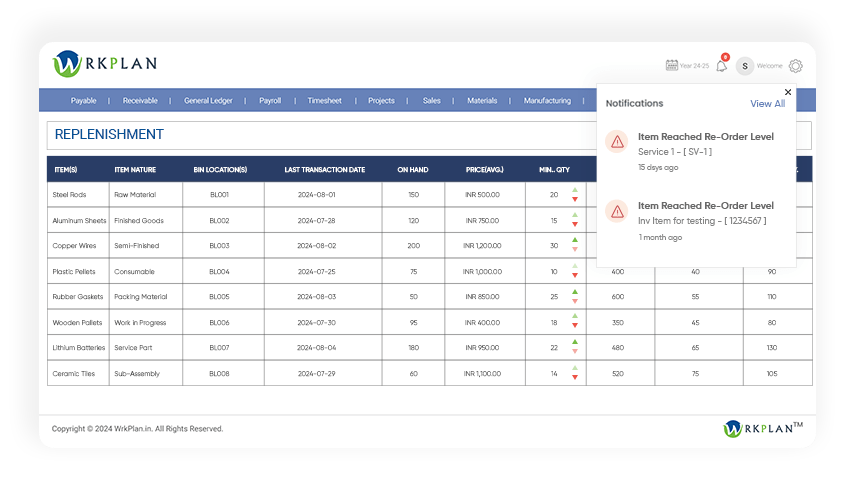

- Inventory Replenishment Alerts

Key Features and Benefits

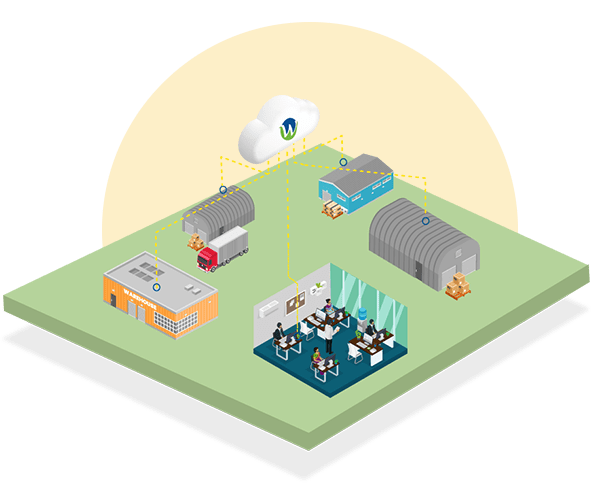

Centralized Database and Real-time Syncing

WrkPlan’s Multiple Warehouse Management system features a centralized database and continuous real-time data syncing, ensuring that all inventory data is consistent and accessible from any location.

-

Centralized Database: All inventory data is stored in a centralized cloud-based database, ensuring that information is always up-to-date and accessible from any location.

-

Real-time Syncing: Continuous real-time data synchronization ensures that inventory changes, transactions, and stock movements are instantly reflected across all warehouses.

Inter-warehouse Stock Transfers

Manage stock transfers between multiple warehouse locations efficiently with WrkPlan’s automated inter-warehouse transfer feature.

-

Automated Requests: Initiate and track stock transfer requests directly within the system, with automated workflows that manage the process from start to finish.

-

Detailed Documentation: Every transfer is fully documented, with records including quantities, item details, and status updates.

-

Automatic Adjustments: Inventory levels are automatically updated in both source and destination warehouses upon transfer completion.

Warehouse-specific Inventory Tracking

Track and manage inventory levels at each warehouse location individually with WrkPlan’s warehouse-specific inventory tracking feature.

-

Unique Identifiers: Assign unique identifiers to each warehouse, enabling precise tracking and management of inventory by location.

-

Segregated Records: Inventory is tracked separately for each warehouse, providing detailed, location-specific stock records.

-

Detailed Reporting: Generate real-time reports for individual warehouses, covering stock levels, transactions, and performance metrics.

Stock Replenishment and Alerts

WrkPlan’s inventory management system includes automated reorder points and real-time alerts to ensure that inventory levels are always optimal.

-

Automated Reorder Points: Set and manage reorder points for each item at each warehouse, triggering automatic replenishment when necessary.

-

Real-time Alerts: Receive instant notifications when critical inventory levels are reached or when replenishment is needed.

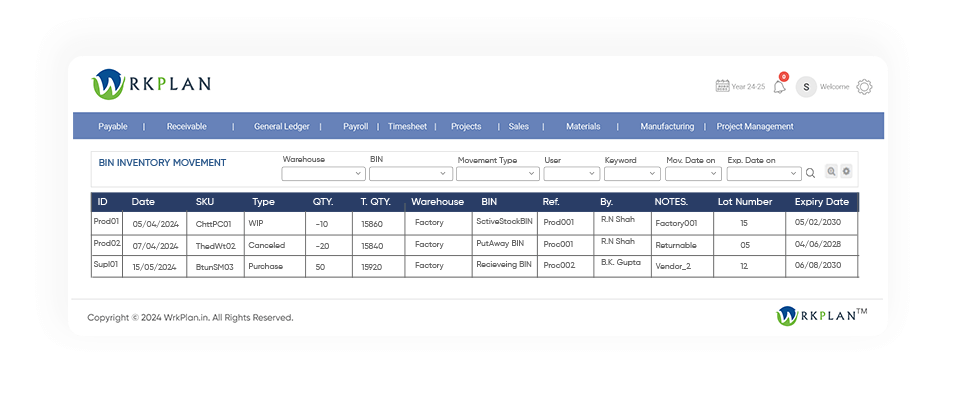

Integration with Other Modules

WrkPlan’s Multiple Warehouse Management system seamlessly integrates with other key modules, ensuring a unified approach to business management.

-

Accounting Integration: Seamless synchronization of inventory data with WrkPlan’s accounting module, ensuring accurate financial records.

-

Warehouse and Manufacturing Integration: Connect with warehouse and manufacturing modules to synchronize receiving, storage, shipping, and production data.

-

Payroll Integration: Link inventory management with payroll to track labor costs related to warehouse operations.

User Permissions and Roles

Maintain control and security over inventory management with WrkPlan’s role-based access control and detailed audit trails.

-

Role-based Access Control: Implement user-specific roles and permissions to control access to inventory data and functions.

-

Audit Trails: Maintain secure, detailed audit logs of all inventory transactions for accountability and compliance.